Table of Contents

What is Order Processing System?

Various activities involved in order processing have been identified in a generic manner till now in the chapter, but it is essential to understand how order processing works in different kinds of organizational systems. An overview of these order processing systems is mentioned in the following paragraphs.

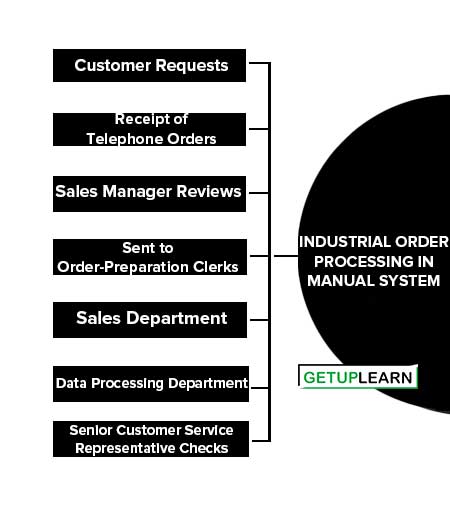

Industrial Order Processing in Manual System

A manual order-processing system is one that has a high component of human activity throughout the system. Some aspects of order processing may be automated or handled electronically, but manual activity will represent the largest portion of the order-processing cycle.

Consider how a hypothetic manufacturer selling to industrial customers designed its order-processing system. Suppose organization X produces a full line of custom hose couplings and valves.

The organization processes 80 orders per day on average with order cycle time is 15 to 25 days, which is long enough due to customization. The primary steps in the order-processing cycle, excluding the order execution activity, are the following:

- Customer Requests

- Receipt of Telephone Orders

- Sales Manager Reviews

- Sent to Order-Preparation Clerks

- Sales Department

- Data Processing Department

- Senior Customer Service Representative Checks

Customer Requests

Customer requests are entered into the order-processing system in two ways. First, salespeople collect orders from the field and mail or telephone them to the organization’s headquarters. Second, customers take the initiative to mail or telephone their orders directly to headquarters.

Receipt of Telephone Orders

Upon receipt of telephone orders, a customer service receptionist transcribes the order to an abbreviated order form. Along with the mailed-in orders, the orders accumulated for a given day are passed along to the senior customer service representative, who then tallies the information for the sales manager.

Sales Manager Reviews

The sales manager reviews the order information to keep abreast of the sales activity. He also occasionally writes special notes of instruction on an order about the needs of a particular customer.

Sent to Order-Preparation Clerks

Next, the orders are sent to the order-preparation clerks, who transcribe the order information, along with special instructions, onto a standard organization order form.

Sales Department

At this point, the orders are sent to the accounting department for credit checks. They are then forwarded to the sales department for price verification.

Data Processing Department

Next, the data processing department keys the order information into the computer to be used for transmission to the plant, for more convenient handling and for easy tracing of the order once in the process.

Senior Customer Service Representative Checks

Finally, the senior customer service representative checks the order in its final form and transmits it via electronic transmission to the appropriate plant. In the same process, an order acknowledgment is prepared for the customer and e-mailed as order verification.

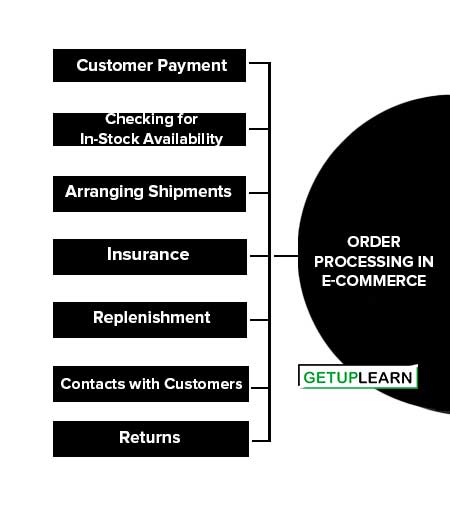

Order Processing in E-commerce

The Web can be used effectively to plan order flows through a supply channel. If the Internet is integrated into the overall planning process, channel members can easily communicate with each other, share relevant information in real-time, and respond quickly and often efficiently to shifts in demand, material shortages, transport delays, and order-filling inaccuracies.

Order status is transparent since all channel members can share a common database, which facilitates tracking and expediting. Low-cost access to the Internet encourages communication among channel partners, which further encourages coordination within the channel, leading to lower ordering costs and improved customer service.

Order processing under e-commerce starts when an order is received and after verification that it is a real order. Several activities take place, some of which can be done simultaneously; others must be done in sequence. These activities include the following steps:

- Customer Payment

- Checking for In-Stock Availability

- Arranging Shipments

- Insurance

- Replenishment

- Contacts with Customers

- Returns

Customer Payment

Making sure the customer will pay as per the order requirement: Depending on the payment method and prior arrangements, the validity of each payment must be determined. In B2B, the organization’s finance department or financial institution (i.e., a bank or a credit card issuer, such as Visa) may do this.

Any holdup may cause a shipment to be delayed, resulting in a loss of goodwill or a customer. In B2C, the customers usually prepay, frequently by credit card or debit card. One more payment mechanism that is getting popular in the B2C segment is Payment on Delivery (PoD).

Checking for In-Stock Availability

Regardless of whether the seller is a manufacturer or a retailer, as soon as an order is received an inquiry needs to be made regarding stock availability.

Several scenarios are possible here that may involve the material management and production departments, as well as outside suppliers and warehouse facilities. In this step, the order information needs to be connected to the information about in-stock inventory availability.

Arranging Shipments

If the product is available, it can be shipped to the customer right away. If the product is readily available, packaging and shipment arrangements need to be made. It may involve both the packaging and shipping department and internal shippers or outside transporters.

Insurance

Sometimes the contents of a shipment need to be insured. This could involve both the finance department and an insurance agency. Again, information needs to flow, not only inside the organization but also to and from the customer and insurance agent.

Replenishment

Customized orders will always trigger a need for some manufacturing or assembly operation. Similarly, if standard items are out of stock, they need to be produced or procured. Production can be done in-house or by contractors.

Contacts with Customers

Sales representatives need to keep in constant contact with customers, especially in B2B, starting with notification of orders received and ending with notification of a shipment or a change in delivery date. These contacts are usually done via e-mail and are frequently generated automatically.

Returns

In some cases, customers want to exchange or return items. Such returns can be a major problem. The movement of returns from customers back to vendors is called reverse logistics.

Order fulfillment processes may vary, depending on the product and the vendor. The order fulfillment process also differs between B2B and B2C activities, between the delivery of goods and services, and between small and large products. Furthermore, certain circumstances, such as in the case of perishable materials or foods, require additional steps.

Retail Order Processing

Organizations, such as retailers, that operate intermediate to vendors and customers frequently design their order-processing systems with at least a moderate degree of automation. Very quick order response time is usually not necessary, since there are inventories available for final consumers.

However, replenishment order cycle times that help to maintain a fixed replenishment schedule are important. Modern information systems have had the benefit of replacing many of the assets previously needed to run a business.

Using the Internet, organizations have been able to reduce warehouse space, lower inventory levels, reduce handling time, and better track order progress. A hypothetical warehouse-free-distribution, direct-to-customer delivery system’s order processing through Electronic Data Interchange (EDI) is explained as:

- The customers tell the distributor how much of which products are wanted and where via EDI.

- The distributor tells the suppliers how much of which products must be shipped via EDI.

- The distributor tells the logistics provider where to pick up the product and how much via EDI.

- The distributor tells the logistics provider how much of which products are to be delivered where and when via EDI.

- The suppliers prepare the product for shipment.

- The logistics provider picks up the product, and sorts and segregates the product to the distributor’s specifications.

- The logistics provider delivers the products to the customers.

FAQs About the Order Processing Systems

What is the order processing in e-commerce?

Order processing under e-commerce starts when an order is received and after verification that it is a real order. These activities include the following steps: 1. Customer Payment 2. Checking for In-Stock Availability 3. Arranging Shipments 4. Insurance 5. Replenishment 6. Contacts with Customers 7. Returns.