Table of Contents

What is Production Management?

The set of interrelated management activities, which are involved in manufacturing certain products, is called Production Management. If the same concept is extended to services management, then the corresponding set of management activities is called Operations Management.

The production and operations management is directly responsible for providing the product; its role is gaining importance. It has become a key discipline in management science. Earlier the field of Operations Management was considered relevant only to the manufacturing sector. However, with the increasing influence of service industries, the scope of Operations Management has widened.

What is Production?

Production is defined as “the step-by-step conversion of one form of material into another form through a chemical or mechanical process to create or enhance the utility of the product to the user.” Thus production is a value-addition process. At each stage of processing, there will be some value addition.

Edwood Buffa defines production as A process by which goods and services are created called production.

Some examples of production are manufacturing custom-made products like, boilers with a specific capacity, constructing flats, some structural fabrication works for selected customers, etc., and manufacturing standardized products like cars, buses, motorcycles, radios, television, etc.

Products and Services

What are Products?

A product is a tangible and identifiable thing. It is the outcome of the series of several transformation processes subjected to it. On the other hand, services are often intangible, which cannot be measured in physical units, however, it can be only felt by the consumer.

Entertainment through a movie, hospitality by a restaurant, knowledge provided by a teacher, and many others, all fall under the category of services. Hence, through a service, it is a customer who is being processed. The deprived customer is the input and the satisfied customer is the output.

Manufacturing is characterized by tangible outputs (products), outputs that customers consume overtime, jobs that use less labor and more equipment, little customer contact, no customer participation in the conversion process (in production), and sophisticated methods for measuring production activities and resource consumption as the product are made.

What are Services?

Service is characterized by intangible outputs, outputs that customers consume immediately, jobs that use more labor and less equipment, direct consumer contact, frequent customer participation in the conversion process, and elementary methods for measuring conversion activities and resource consumption.

Some services are equipment based namely rail-road services, and telephone services, and some are people-based namely tax consultant services, hair styling, etc. Many definitions of service are available; however, all of them have some common themes like intangibility and consummation at the same time.

Definition of Service

A service is an activity or series of activities of more or less intangible nature that normally, but not necessarily, take place in interactions between customer and service employees and/or physical resources or goods and /or systems of the service provider, which are provided as solutions to customer problems.

Getuplearn

A precise definition of goods (products) and services should distinguish them on the basis of their attributes. Good is a tangible physical object or product that can be created or transferred; it has an existence over time and thus can be created and used later. A service is intangible and perishable.

Getuplearn

It is an occurrence or process that is created and used simultaneously. While the customer cannot retain the actual service after it is produced, the effect of the service can be retained.

Production and Operations Management

The set of interrelated management activities, which are involved in manufacturing certain products, is called production management. If the same concept is extended to services management, then the corresponding set of management activities is called as operations management.

Production and Operations Management (POM) may be defined as the design, operation, and improving the process of transformation. POM converts the various inputs into the desired outputs of products as well as services.

Production and Operations management is the management of direct resources (machine, material, and manpower), which are required to produce goods and services. It includes managerial functions of planning, organizing, controlling, directing, and coordinating all the activities related to production systems.

In operations management, the firm transforms resource inputs into value-added products or services. It deals with the design of products and processes, acquisition of resources, transformation, etc.

The production process transforms not only the resources but also the expertise of an organization into higher-value goods and services. It takes inputs from the market environment and the organization’s own technological capabilities and then converts these into an economically efficient and productive activity.

Product Design

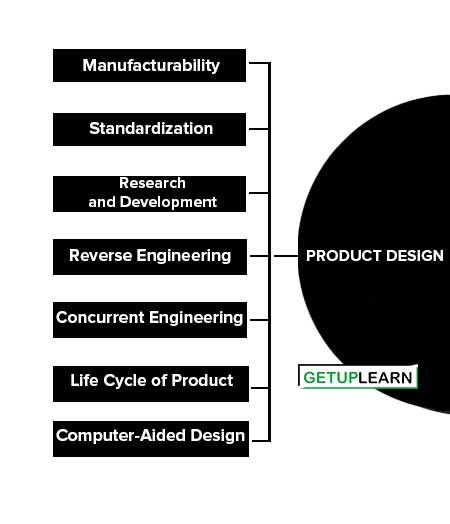

While determining the product design, the organizations have to ponder over the following concepts:

- Manufacturability

- Standardization

- Research and Development

- Reverse Engineering

- Concurrent Engineering

- Life Cycle of Product

- Computer-Aided Design

Manufacturability

Manufacturability means designing a product in such a manner that its assembling or manufacturing may be performed in an easy way. Manufacture capabilities of a firm may be recognized by reviewing its existing machines, skills of workers equipment, etc.

Standardization

Standardization means producing goods on certain fixed standard specifications. There is no major variation from the existing products while developing some new products.

For example, we see that there are many companies and brands which manufacture lighting and fixture, but each company follows standard specifications and parameters. Standardization provides many benefits like lower design cost, easy availability of components, etc.

Research and Development

Research and development help in designing new products. Research may be of two types; fundamental research and applied research. Fundamental research is the advancement of the state of knowledge in a particular discipline.

On the other hand, applied research is the development of commercial applications based on fundamental research. When the outcome of the applied research is converted into a useful commercial application, it is known as development.

Reverse Engineering

As the name suggests, it is the reverse process of manufacturing. Reverse engineering is the process of dissecting and dismantling an already existing product in a step-by-step manner to understand and analyze the uniqueness of the product. This process helps in designing new products.

Concurrent Engineering

Under this approach to product design, a comprehensive design team is framed. This design team includes personnel from each and every department; like persons from the engineering department to analyze the feasibility of the product; persons from the marketing department to present the customer requirement.

Persons from the production department to suggest the production capabilities; persons from the finance department to explore the finance feasibility; persons from the materials department to examine the material available for the new specification of the product.

Life Cycle of Product

Like humans and other species, each product has a life cycle. The life cycle of a typical product passes through four stages. The first stage in the life cycle of a product, after it is designed and developed, is the introduction stage. In this stage, sales are dependent on promotion and other marketing efforts.

Profits are either negative or almost negligible. The products that successfully survive in this stage enter into the next stage, which is known as the growth stage. In the growth stage, sales volume increases in an exponential manner. During the growth stage, firms take decisions regarding the expansion of their existing production capacity.

These decisions are taken on the basis of response to the product in the market. The third stage of the product life cycle is termed as growth stage. In this stage, sales growth becomes almost stagnant. During the maturity stage, firms work on improving their efficiency of the processes, minimizing costs, etc.

In the final stage i.e. decline stage, the product sales show a downward trend. It is due to the obsolescence of technology used in the production. The other factors behind it are changing customer requirements and the availability of substitute or complementary products.

Computer-Aided Design

Computer-aided design (CAD) based on software, facilitates the designer to develop the three-dimensional design of a product on a display monitor. An analysis of the design from multiple perspectives is possible through CAD.

With the help of advanced CAD systems engineers can test the performance of their design through computer simulation. CAM (computer-aided manufacturing) is a specialized computer system, which converts CAD design information into instruction for numerically controlled automated machines.

FAQs About the Production Management

What is product design?

Product-focused design is also known as a line flow production system. This type of processing system is used mostly in production departments that are organized according to the type of product or service being produced. Products or services usually flow along linear paths.