Table of Contents

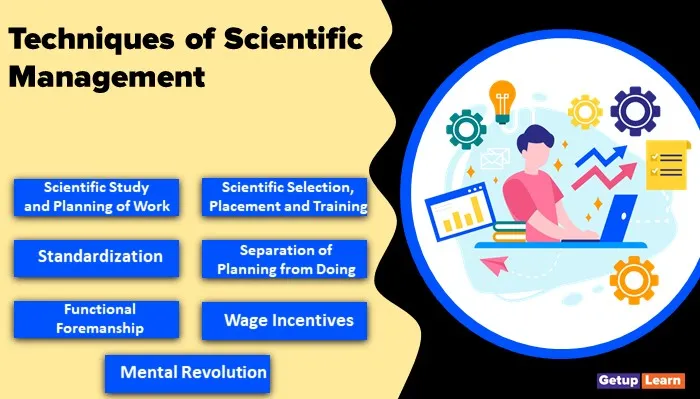

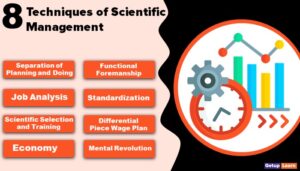

Techniques of Scientific Management

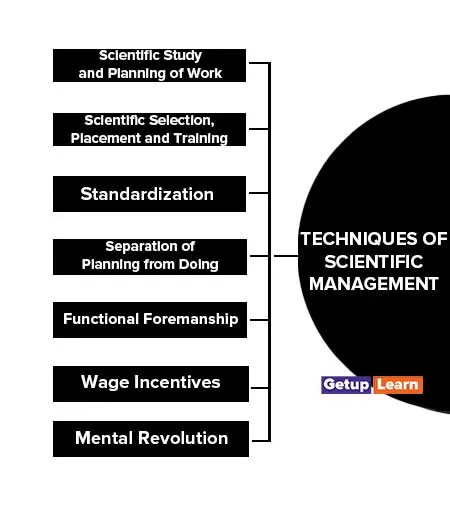

Based on his experience on the shop floor Taylor has suggested the following 7 techniques of scientific management:

- Scientific Study and Planning of Work

- Scientific Selection, Placement and Training

- Standardization

- Separation of Planning from Doing

- Functional Foremanship

- Wage Incentives

- Mental Revolution

Scientific Study and Planning of Work

The management should study each element of work scientifically and decide the daily standard output for each worker. For this purpose time and motion study should be conducted. Time study will help to determine the standard time required to do a job.

Motion study will help to remove unnecessary movements of workers in doing the job. With the help of this technique, the management can give a precise idea to the workers on what is to be done and how it can be done efficiently.

Scientific Selection, Placement and Training

The workers should be selected by using scientific methods and not relying on the intuition and judgment of the foreman. They should be placed on the right job by matching job requirements with their capacity and attitude.

Further, they should be trained on a regular basis to do the task in the best manner and give maximum output at minimum cost.

Standardization

Taylor advocated the importance of standardization of tools, equipment, raw materials, quality of work and physical working conditions.

Separation of Planning from Doing

The planning function should be separated from the doing function to secure the benefits of division of work and specialization. Planning of work should be the responsibility of management. The management should plan, organize and direct the work whereas the workers should implement the plans.

Functional Foremanship

Taylor was the first to introduce and practice the concept of functional foremanship. According to Taylor, instead of having one foreman, there should be four Supervisors in the shop room namely, the gang boss, the speed boss, the repair boss and the inspector.

In the planning office there should be four specialists namely the time and cost clerk, the instruction card clerk, the order of work and route clerk and the shop disciplinarian. Under functional foremanship, each worker should receive orders directly from these eight different supervisors dealing with different aspects of his job.

Wage Incentives

Taylor suggested paying workers according to their efficiency. Workers producing more should be given higher wages. He devised a differential price rate plan which implies different rates of wages for different levels of efficiency of workers.

The efficient worker should get more wages than the average worker. The introduction of a wage incentive scheme will reward the efficient worker and punish the inefficient worker.

Mental Revolution

For getting the desired results of scientific management Taylor emphasized the need for a mental revolution i.e. a fundamental change of outlook on the part of both employer and employees. The workers should change their attitude, outlook and behaviour as to their duties, their work, their fellowmen and their employer.

At the same time, the management should change its attitude, outlook and behaviour towards the workers and their problems. Instead of having a hostile attitude and engaging in continuous conflict, management and workers should cooperate with each other and work for their mutual benefit.

They should give up the perception that any gain by one is at the expense of another. Their relationship should be cordial, cooperative and positive. There should be no hostility, distrust and suspicion between them.

What are the techniques of scientific management?

The following are the techniques of scientific management:

1. Scientific Study and Planning of Work

2. Scientific Selection, Placement and Training

3. Standardization

4. Separation of Planning from Doing

5. Functional Foremanship

6. Wage Incentives

7. Mental Revolution.

What are the techniques of scientific management explain in detail.

Scientific management is a management theory developed by Frederick W. Taylor in the late 19th and early 20th centuries. The main goal of scientific management is to increase efficiency and productivity by applying scientific methods to the management of work processes. The following are some of the key techniques of scientific management:

1. Time and Motion Study

2. Work Specialization

3. Standardization

4. Scientific Selection and Training of Workers

5. Management by Objectives

6. Functional Foremanship.